Motorized 6 axis Stages

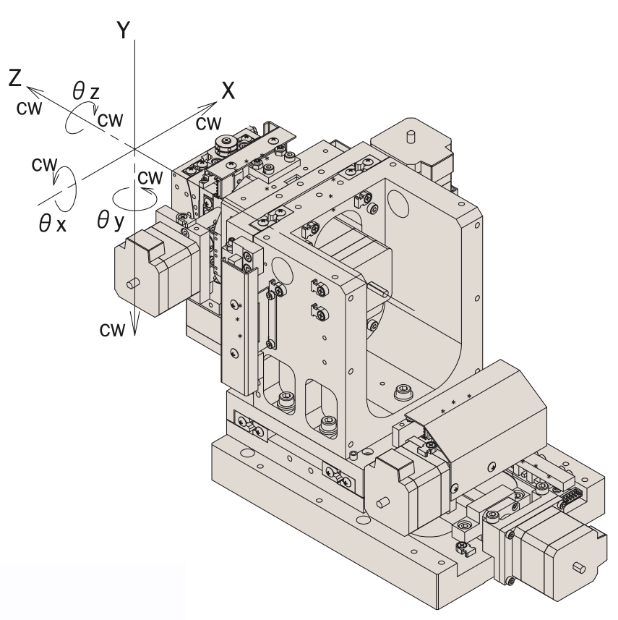

Compact 6 axis Manipulator [MPS Series]

-

MPS-SSSD-B010

-

Example of UseAssembly of 3-plate LCD projectors, medical cameras, etc.FeaturesEmphasizes rigidity, downsizing, and weight reduction.

Height 50% down

Width 40% down

Weight 30% down

Rigidity 30% up

Various requested modifications, such as changing the stroke of the axis for retreat, are available.

Ideal for positioning when attaching elements of LCD projectors and CCD cameras, and for fine positioning when attaching devices.

Product Specifications

| Axis Name | Travel Range *1 | Maximum Speed | Resolution *2 | Driver Divisions |

|---|---|---|---|---|

| X | ±5mm | 1mm/sec | 0.1μm | 1/10 |

| Y | ±5mm | 1mm/sec | 0.1μm | 1/10 |

| Z | ±5mm | 10mm/sec | 0.1μm | 1/10 |

| θx | ±3° | 3.8°/sec | Approx. 0.00038° | 1/2 |

| θy | ±3° | 2.8°/sec | Approx. 0.00028° | 1/2 |

| θz | ±3° | 18°/sec | 0.0018° | 1/4 |

*2 Resolution can be changed by setting the number of driver divisions.

Axis Configuration(Click on the drawing to enlarge)

Dimensions(Click on the figure to enlarge)

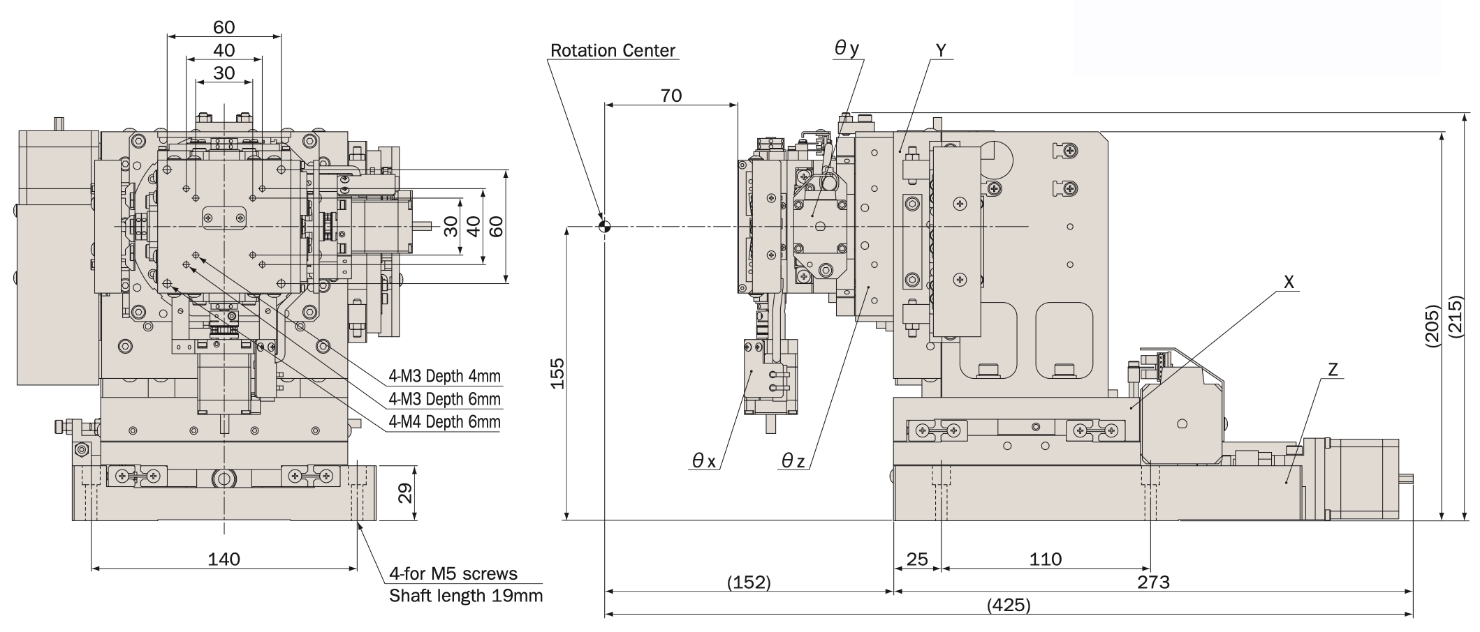

Compact 6 axis Manipulator [SMR Series]

-

SMR-6B201

-

Example of UseAssembly of small camera modules such as mobile and in-vehicle camerasFeaturesThe 6-axis unit with an integrated automatic XYθ stage is ultra-compact and space-saving.

With few protruding parts, it can be installed in a limited and extremely small space.

Ball screws are used for all axes for increased durability.

Sub-micron accuracy is achieved through design and assembly adjustments that emphasize rigidity.Advantages of AdoptionIdeal for alignment (image processing) as production/inspection equipment for various electronic components.

Stages with enhanced rigidity provide better positioning accuracy and responsiveness, shortening alignment time and improving production takt time and yield rate.

Product Specifications

| Axis Name | Travel Range | Maximum Speed | Resolution (half step) |

|---|---|---|---|

| X | ±3mm | 10mm/sec | 1μm |

| Y | ±3mm | 10mm/sec | 1μm |

| Z | ±2.5mm | 1.25mm/sec | 0.125μm |

| θx | ±5° | 11.3°/sec | Approx. 0.000378° |

| θy | ±4.5° | 8.5°/sec | Approx. 0.000282° |

| θz | ±3° | 12.7°/sec | 0.00127° |

Dimensional Drawings(Click on the drawing to enlarge)

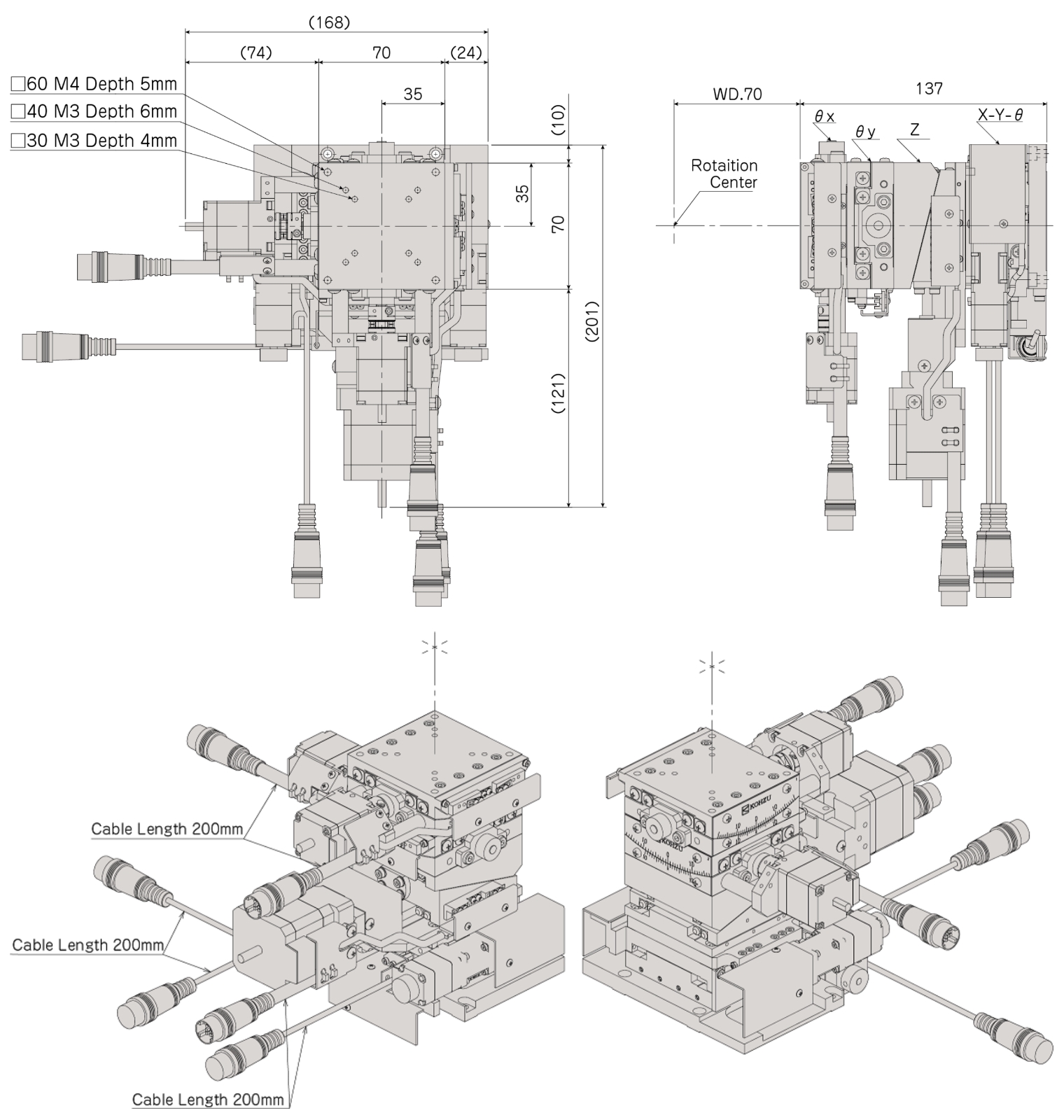

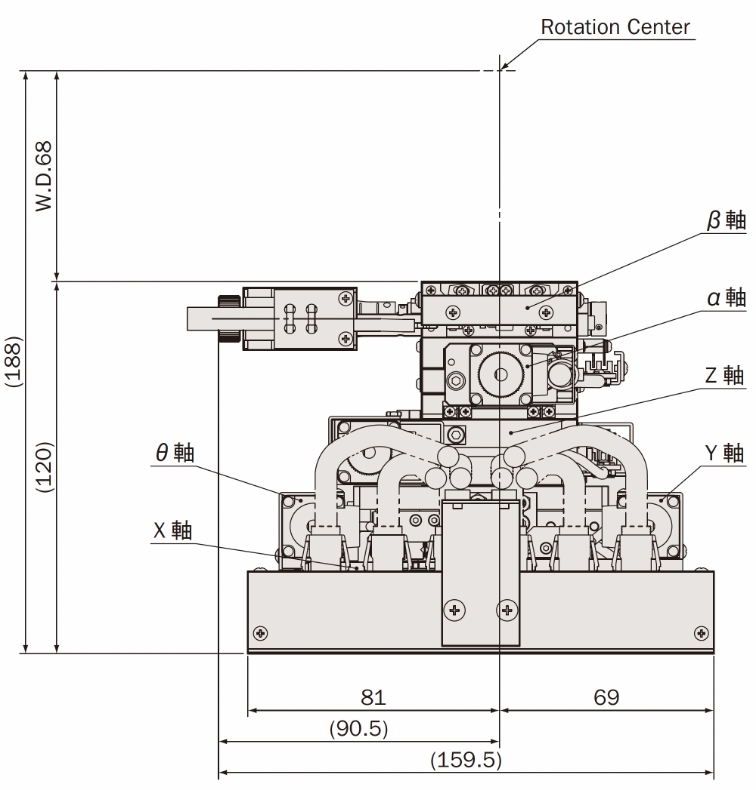

Compact 6 axis Manipulator [USM Series]

-

USM-R1C-010

-

Example of UseAssembly of camera modules and small semiconductor devicesFeaturesRigidity-oriented, ultra-compact and lightweight, centralized connector, high tracking performance in positioning.

Compact and lightweight while maintaining high accuracy and rigidity.

Ball screw drive in all axes ensures long life and reproduces stable accuracy for a long period of time.

Centralized Connector Unit

Wiring for motors and sensors for 6 axes are concentrated in one place, facilitating troublesome multi-axis wiring work. (The unit can also be removed when not needed.)

Centralized Connector Unit

Light weight (approx. 3 kg) enables mounting on transport axes operating at high speeds

High Tracking Performance

The system has sub-micron tracking in the linear direction and second tracking in the angular direction, and completes positioning to the commanded value with high accuracy.

Reference example: The follow-up data for a single-pulse feed of a swivel stage shows that the error is within ±0.0002 deg. compared to 0.000797 deg.

Product Specifications

| Axis Name | Travel Range | Maximum Speed | Minimum Resolution | Driver Divisions |

|---|---|---|---|---|

| X | ±3mm | 10mm/sec | 0.1μm | 1/20 |

| Y | ±3mm | 10mm/sec | 0.1μm | 1/20 |

| Z | ±1.5mm | 2.5mm/sec | 0.025μm | 1/20 |

| θ | ±3° | 12.7°/sec | 0.000127° | 1/20 |

| α | ±3° | 9.6°/sec | Approx. 0.0000637° | 1/20 |

| β | ±3° | 12°/sec | Approx. 0.0000797° | 1/20 |

Dimensional Drawing(Click on drawing to enlarge)

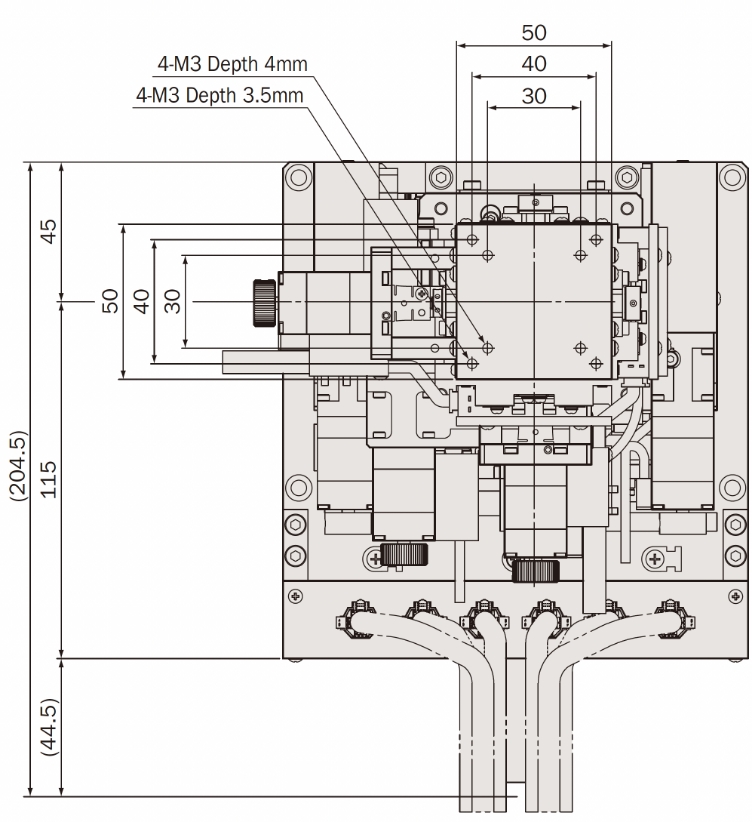

Flexible Customization

Flexible combinations

-

Center of rotation Downward

Center of rotation Downward -

Reverse use

Reverse use -

Ball screw drive on all axes

Ball screw drive on all axes -

Space around workpiece is secured

Space around workpiece is secured -

Combined use with conveyor axis

Combined use with conveyor axis -

Cable bear mounting

Cable bear mounting